SERVICES

Reliance is truly an end to end provider of claims and accident management services. Here you will find a list and description of the multitude of services we offer.

Insurance Accident Claim

24-Hours Towing Service

Autovehicle Body

Aircon Servicing

Panel Beating & Welding

Spray Painting

Wheel Alignment & Balancing

Cushion Upholstery

Electrical Wiring Work

Engine Repair / Overhaul

Windscreen Repair / Replace

Car Wash And Polish

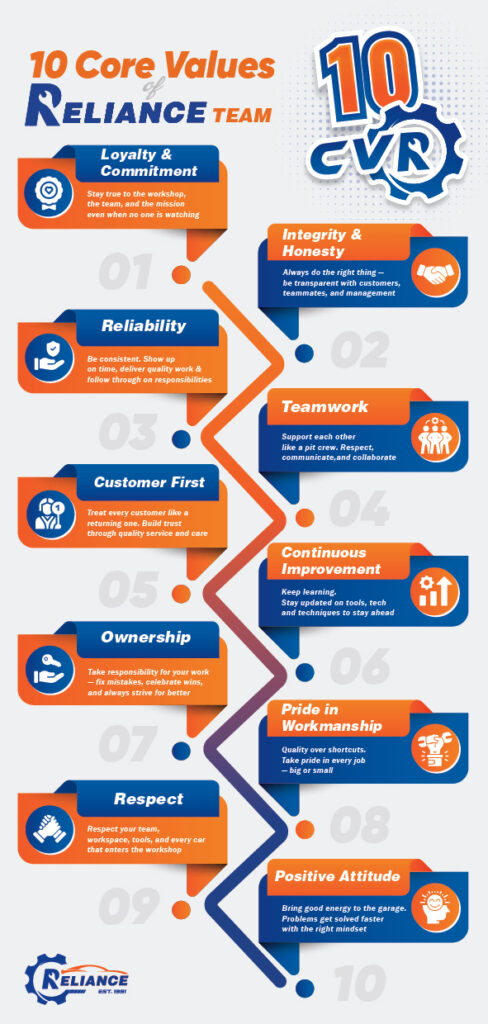

The Values Behind Every Repair

At Reliance Workshop, every service we provide is guided by our core values — Reliability, Integrity, Quality, and Safety.

These values shape how we diagnose, repair, and deliver every vehicle. From precision bodywork to electric vehicle repair, our team upholds strict safety protocols and professional standards to ensure every journey continues with confidence.

Loyalty & Commitment

Integrity & Honesty

Reliability

Teamwork

Customer First

10 Core Values

Continuous Improvement

Ownership

Pride in Workmanship

Respect

Positive Attitude

6S Reliance Power System

The 6S system is an enhanced version of the 5S workplace organization method that originated in Japan. It’s a structured approach to create a clean, efficient, and safe working environment, especially in industries like automotive workshops, manufacturing, and logistics.

The sixth ‘S’—Safety—was personally introduced by our Director, Mr. Anthony Chin, to remind us that no efficiency or excellence matters without the well-being of our people.

1. Sort (Seiri)

1. Sort (Seiri)

Meaning: Remove unnecessary items from the workplace — keep only what’s needed.

Why:

-

Reduces clutter and confusion.

-

Makes it easier to find tools and materials.

-

Improves workflow and safety (less tripping hazards, fewer misplaced items).

2. Set in Order (Seiton)

2. Set in Order (Seiton)

Meaning: Arrange all necessary items so they are easy to access and return.

Why:

-

Saves time searching for tools or parts.

-

Reduces movement and improves productivity.

-

Ensures a logical, safe layout for work processes.

3. Shine (Seiso)

3. Shine (Seiso)

Meaning: Clean the workspace and equipment regularly.

Why:

-

Prevents dirt buildup and potential hazards.

-

Encourages ownership and pride in the workspace.

-

Helps detect leaks, wear, or other early maintenance issues.

🔹 4. Standardize (Seiketsu)

Meaning: Establish consistent procedures and visual controls for the first three steps.

Why:

Maintains organization and cleanliness over time.

Makes the system easy to follow for everyone.

Promotes accountability and teamwork.

🔹 5. Sustain (Shitsuke)

Meaning: Build discipline to keep the 5S process going — make it part of the culture.

Why:

Ensures long-term success of all improvements.

Builds positive work habits and teamwork.

Encourages continuous improvement (Kaizen mindset).

🔹 6. Safety (added in the modern 6S version)

Meaning: Integrate safety into every step of the process.

Why:

Protects workers from injury.

Reinforces the company’s care for its people.

Prevents accidents through proactive design and awareness.

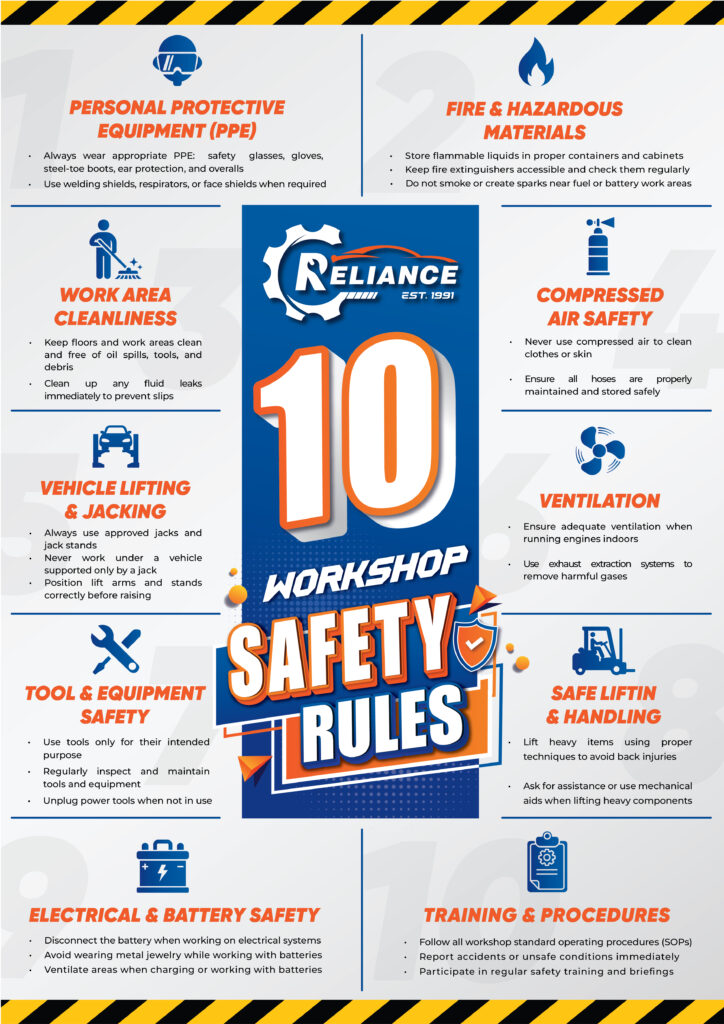

Reliance Workshop – 10 Safety Rules

Personal Protective Equipment (PPE)

Always wear proper safety gear such as gloves, glasses, ear and eye protection, and steel-toe boots.Fire & Hazardous Materials

Store flammable liquids safely, keep extinguishers accessible, and avoid open flames near fuels or batteries.Work Area Cleanliness

Keep floors and work areas clean, dry, and free from debris to prevent slips and accidents.Vehicle Lifting & Jacking

Use approved jacks and stands correctly — never work under a vehicle supported only by a jack.Tool & Equipment Safety

Use tools properly, maintain them regularly, and unplug when not in use.Compressed Air Safety

Never use compressed air to clean skin or clothing; inspect hoses regularly.Ventilation

Ensure good airflow when running engines indoors; use exhaust extraction systems.Safe Lifting & Handling

Use correct lifting techniques or mechanical aids to prevent back injuries.Electrical & Battery Safety

Disconnect batteries before electrical work and ensure proper ventilation during charging.Training & Procedures

Follow SOPs, report unsafe conditions, and join regular safety briefings.

As a growing global business, Reliance believes performance and success begins with fixing every vehicle to a high quality, and high safety standard.

These quality standards are backed by our day to day commitment to provide excellent customer care and service.

Find Us

- 29, Wisma Bantu, Jalan Dua, Jalan Chan Sow Lin, 55200 Kuala Lumpur, Malaysia

- relianceworkshopmy@gmail.com

-

24H Towing Service Team :

+603-9221 5488 / +6017-381 1198 -

Customer Service :

+603-9221 8488 / +6017-291 1198